SAFETY, HEALTH AND ENVIRONMENT

SAFETY, OCCUPATIONAL HEALTH AND ENVIRONMENT (SHE)

Thai Union is one of the world’s leading seafood producers, firmly committed to responsible environmental and social performance across our global operations. We recognize that safeguarding our people, communities, and the environment is fundamental to our long-term business success.

In 2023, we launched SeaChange® 2030, our enhanced sustainability strategy that builds on the foundations of the original SeaChange® program introduced in 2016. The updated strategy is anchored in three core commitments:

- Path to Net Zero Emissions

- Best-In-Class Manufacturing

- Safe, Decent, and Equitable Work.

These pillars guide our corporate responsibility framework and embed safety, occupational health, and environmental (SHE) considerations into daily operations, decision-making processes, and risk management practices.

As part of our governance approach, Thai Union has established and implemented robust environmental and occupational health policies. These are communicated across all levels of the organization and to external stakeholders, ensuring alignment with our enterprise-wide sustainability objectives. The policies address key operational impacts on our employees, ecosystems, and surrounding communities; and they are subject to regular internal reviews and external audits.

We provide mandatory SHE training to all employees and empower them to take an active role in achieving sustainability targets. This fosters a culture of shared accountability and continuous improvement while enhancing compliance with international frameworks and stakeholder expectations.

Thai Union continuously strengthens its safety management systems through audits, risk assessments, performance monitoring, and transparent reporting. Our integrated approach ensures that environmental protection, occupational health, and safety performance are monitored through clear KPIs, which support our contribution to the UN SDGs and fully align with the DJSI framework.

SAFETY, HEALTH AND ENVIRONMENT POLICY

At Thai Union, we are committed to operating responsibly by protecting the health and safety of our people, preserving the environment, and supporting community well-being. Our Safety, Health, and Environment (SHE) Policy serves as a framework for integrating these priorities across all operations.

The policy applies to all Thai Union entities, including subsidiaries, and is mandatory for employees, contractors, and supervised personnel. Through strong leadership, accountability, and a culture of shared responsibility, we strive to build a resilient, safe, and sustainable seafood industry, fully aligned with local and international standards.

For more information on Thai Union’s SHE policy, please see here.

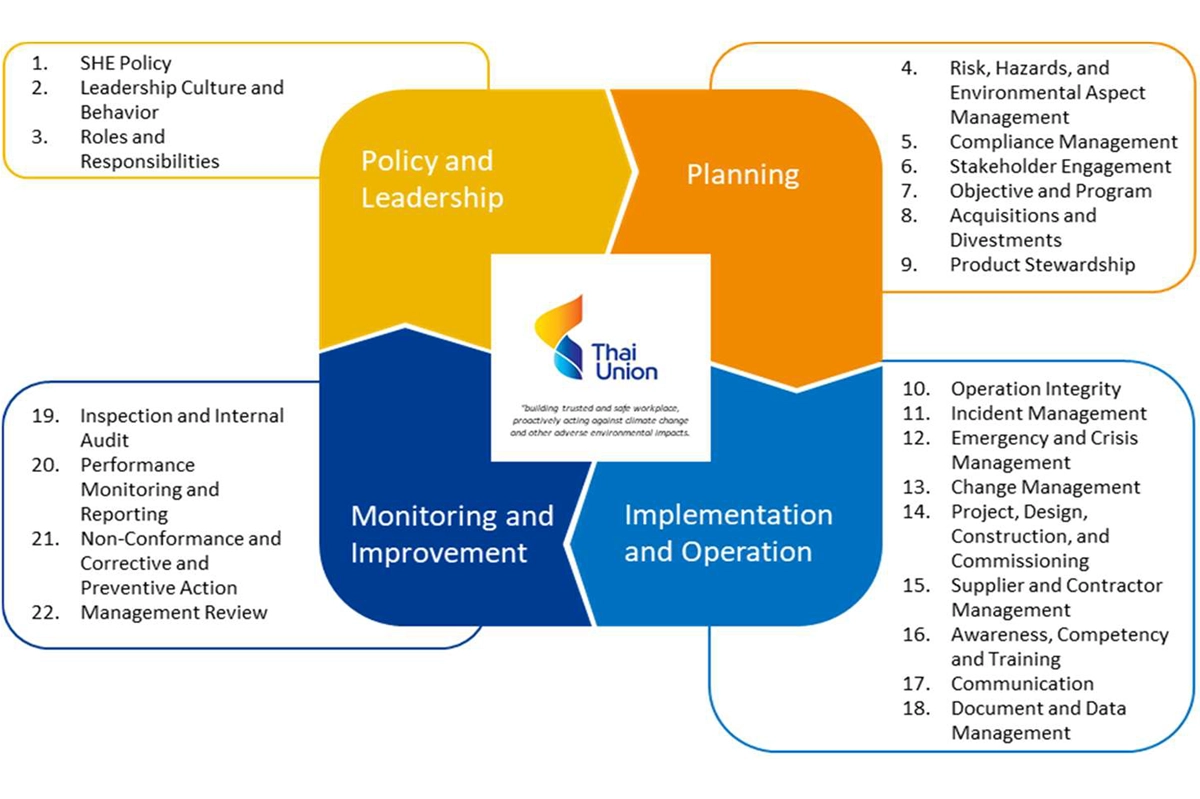

SAFETY, OCCUPATIONAL HEALTH, AND ENVIRONMENT (SHE) MANAGEMENT FRAMEWORK

Thai Union’s Safety, Health, and Environment (SHE) division is dedicated to establishing and maintaining robust protocols that ensure all employees, contractors, and personnel working on behalf of the company are informed of and comply with SHE requirements. Our goal is to minimize environmental impact and provide a safe and healthy workplace across our operations.

To support the effective implementation of the SHE Management Framework, we have developed a comprehensive set of SHE Guidelines. These provide site-level teams with step-by-step procedures tailored to address specific risks, hazards, and environmental impacts.

Across our major manufacturing facilities, our health, safety, and environmental management systems are independently verified against internationally recognized standards such as ISO 45001, ISO 14001, MSC, and ASC. Focusing certification on these key sites ensures robust risk management, drives continuous improvement, and underscores Thai Union’s commitment to operational excellence and sustainable development.

SAFETY IN THE WORKPLACE

At Thai Union, we are committed to protecting our people and the environment through a structured and proactive approach to Safety, Health, and Environment (SHE) management. As part of our SHE system, risks are assessed and addressed through the RACE framework, which stands for Recognizing, Assessing, Controlling, and Evaluating potential risks. Action plans are implemented at the site level and integrated into ongoing safety system improvements. These actions are aligned with our long-term safety objectives and linked to measurable Lost Time Injury Frequency Rat (LTIFR) performance targets.

Further, we are committed to strengthening our health and safety activities through engagement of our employees and will continue to work towards our goal by:

- Implementing robust safety training programs to enhance employee awareness and skills.

- Conducting regular safety audits and inspections to identify and mitigate potential hazards.

- Promoting a proactive approach to hazard identification and risk assessment to identify potential risks in the workplace.

- Verifying SHE performance systems periodically, through internal and external evaluations, to assess conformance and drive continual improvement

Our Progress

We are committed to achieving zero accidents and injuries, with a goal to reduce LTIFR to below 0.15 by 2030, using 2021 as the baseline; and we are making measurable progress toward these goals

| % LTIFR reduction | |

|---|---|

| From baseline 2021 | 43.6% |

| Year on year between 2023-2024 | 4.35% |

"At Thai Union, we do not compromise on health and safety standards. Every employee is empowered to make their personal safety, that of their colleagues and that of our subcontractors a shared responsibility. To achieve this, we equip them with the skills and equipment necessary to protect themselves and others."

Thiraphong Chansiri, President and CEO

PATH TO NET ZERO EMISSIONS

Climate Action

At Thai Union, we are proud to be the first seafood company to set a greenhouse gas (GHG) emissions reduction target approved by the Science-Based Targets initiative (SBTi) in alignment with the 1.5°C pathway of the Paris Agreement. Our approach involves close collaboration with suppliers, participation in climate alliances, and investment in innovation and R&D to decarbonize our value chain. We are committed to transparency through public disclosures, including our sustainability report and climate indices. Internally, we embed a low-carbon mindset through employee training, cross-functional collaboration, and performance-linked incentives from the internal carbon pricing, driving a just, inclusive, and resilient transition to net zero.

Strategic Enabler for Decarbonization

We are enhancing the monitoring program at the process and equipment level to drive data-based decisions and efficiency improvements.

A structured system is in place to capture and scale successful decarbonisation initiatives across all sites as Group-wide standards.

GHG performance is now integrated into financial planning to prioritise projects with both cost and climate impact benefits.

We are fully phasing out coal in manufacturing by 2030 and shifting to cleaner, low-carbon energy sources

We train employees and share best practices to embed a GHG reduction mindset across the organisation. This includes cross-functional collaboration, internal awareness campaigns and efforts to mitigate potential negative effects of climate transition on roles, skills, and operations

As part of our SeaChange® 2030 global sustainability strategy, we are committed to:

- Reducing Scope 1 and 2 GHG emissions by 42% by 2030, using 2021 as the baseline and

- Achieving net-zero GHG emissions across our value chain by 2050.

We are making measurable progress toward these goals:

| Absolute GHG emission reduction (mt Co2e) | |

|---|---|

| From baseline 2021 | Achieved 21% |

| Year on year between 2023-2024 | Achieved 7% |

These milestones reflect our ongoing efforts to build a more sustainable and resilient seafood industry for future generations.

Energy Management and Renewable Energy

Our approach to energy decarbonization focuses on close collaboration with suppliers and active participation in energy and climate alliances. We also make strategic investments in clean technologies, innovation, research and development (R&D), with a focus on integrating energy performance into the design and upgrade of equipment, systems, and on-site renewable energy installations such as solar rooftops. Energy performance is tracked through internal KPIs and contributes to broader greenhouse gas (GHG) reduction targets. These metrics are currently being assessed for integration into staff performance evaluations and incentive schemes, supported by our ongoing internal carbon pricing study.

Our approach includes:

- Energy Efficiency

Upgrading equipment and optimizing processes to reduce energy use per ton of product. - Real-Time Monitoring

Digital systems to track energy consumption, helping teams quickly spot and fix inefficiencies. - Renewable Energy Expansion

Increasing solar rooftop use, sourcing green electricity, and exploring power purchase agreements (PPA). - Energy Audits

Regular audits to support continuous energy performance improvement. - Team Capacity Building

Training our teams and sharing best practices (e.g. steam reduction guidelines for boiler, pre-cooker, retort, etc.) to embed an energy-saving mindset across the business.

These actions support our 2030 emissions reduction targets, energy consumption reduction objectives, and ensure long-term operational sustainability.

Our Progress

We are committed to reducing our energy intensity by 10% by 2030, using 2021 as the baseline and we are making measurable progress toward these goals.

| Energy intensity reduction (% GJ/TFG) | Coal consumption (% GJ) | Solar consumption (% GJ) | |

|---|---|---|---|

| From baseline 2021 | Achieved 8% | 46% | 257% |

| Year on year between 2023-2024 | Achieved 13% | 37% | 23% |

Explore Thai Union’s Energy Management program and Energy Audit

WATER MANAGEMENT

Thai Union recognizes water as a critical and increasingly scarce resource, essential to our operations and the communities we serve. Our water management approach focuses on reducing water consumption, maximizing recycling and reuse, and achieving zero water discharge at key facilities. By proactively addressing water risks through targeted strategies and innovative solutions, we continuously advance toward our SeaChange® 2030 sustainability commitments, ensuring responsible stewardship of water resources in alignment with global best practices.

Key Measures in Our Water Strategy:

- Water use assessments are conducted regularly to review and analyze site-level water consumption patterns, identify activities with significant water use, and determine opportunities for improved water efficiency.

- Water efficiency tracking: We set internal targets to reduce water-use intensity and monitor them through centralized performance systems.

- Water reuse systems: We are scaling up recycling at key facilities, with a goal of Zero Discharge by 2030.

- Wastewater treatment and monitoring: All major facilities are equipped with on-site wastewater treatment systems, including regular effluent sampling and discharge quality monitoring, to ensure compliance with environmental regulations and to improve the quality of discharged water.

- Flood preparedness: Every factory has a tailored emergency plan to address flood risks and climate-related disruptions.

- Employee awareness and training: We provide mandatory training to all employees, including dedicated modules on water conservation. This ensures staff understand their role in supporting site-level reduction targets and implementing water-saving practices.

These measures are embedded within our Enterprise Risk Management (ERM) framework and are reviewed regularly at both the site and corporate levels. Our approach covers short-, medium-, and long-term time horizons, ensuring we remain agile and resilient in the face of evolving climate-related challenges. In alignment with the Task Force on Climate-related Financial Disclosures (TCFD), we disclose how climate risks—particularly water-related risks—impact our operations. Beginning in 2025, we will adopt the IFRS S2 Climate-related Disclosures Standard, issued by the International Sustainability Standards Board (ISSB), further strengthening the transparency and comparability of our climate risk reporting.

Our Target and Progress

We are committed to reducing municipality water intensity reduction by 10%, using 2021 as the baseline and we are making measurable progress toward these goals

| Progress | Water intensity reduction (% GJ/TFG) | Facilities with zero discharge status |

|---|---|---|

| Year on year between 2023-2024 | Achieved 6% | 1/5 |

In addition, almost 20% of our total water use came from rainwater harvesting, seawater intake, and other alternative sources.

Explore Thai Union’s Water management and zero discharge case study here

Waste Sent to Landfill Reduction

At Thai Union, we are committed to minimizing our environmental impact through a robust and strategic waste management approach that follows the internationally recognized waste management hierarchy.

Our focus begins with waste prevention at the source. We conduct regular waste audits across our operations to identify key waste streams and determine the root causes of waste generation. These insights are integrated into performance reviews and operational planning to prioritize reduction efforts where they will have the greatest impact.

We promote the reuse and recycling of materials wherever feasible and collaborate with partners to identify circular opportunities within our processes.

Recovery methods, including energy recovery, are applied for non-recyclable waste, ensuring maximum value is extracted before final disposal.

To drive continuous improvement, we:

- Set quantitative waste reduction targets, including reducing the volume of waste sent to landfills.

- Monitor waste intensity metrics.

- Integrate findings into our environmental KPIs.

- Share best practices across sites.

We also provide regular training to employees to raise awareness and build capabilities in waste management practices, aiming to reduce waste generation.

By embedding waste reduction into our operational culture and supplier expectations, we move closer to our goal of achieving zero waste to landfill by 2030, in alignment with our SeaChange® strategy.

Our progress of waste sent to landfills intensity reduction

We are committed to reducing our waste sent to landfill intensity by 10% by 2030, using 2021 as the baseline; and we are making measurable progress toward these goals

| Waste sent to landfill intensity reduction (% MT/TFG) | Zero waste sent to landfills of five facilities | |

|---|---|---|

| From baseline 2021 | Achieved 2% | - |

| Year on year between 2023-2024 | Achieved 16% | 2/5 |

Food Loss

Thai Union is committed to reducing food loss across all stages of production and eliminating food waste sent to landfill. Our approach focuses on maximizing the value of every edible input, particularly seafood raw materials, while minimizing losses during handling, processing, and storage.

To eliminate food loss to landfill by 2030 in line with our SeaChange® 2030 strategy, we have implemented a systematic food loss tracking process to measure and monitor food loss by destination and invest in innovation and R&D. We partner with key stakeholders to scale up zero food waste initiatives. Moreover, we process edible materials for multiple uses:

- Recovered for human consumption

- Reprocessed for animal feed, such as aquaculture

- Diverted for energy, such as biogas, or fertilizer

- Repurposed for pet food

Our Progress

We are committed to achieving zero food loss to landfill by 2030, using 2021 as the baseline and we are making measurable progress toward these goals

| % Divert from landfill | |

|---|---|

| Zero food loss status | 99.3 % |

The achievement of zero food loss sent to landfill is not limited to our five major facilities—it represents the collective commitment and broader success of the entire Thai Union Group.

Zero Food Loss Combustible

In 2024, Thai Union achieved zero food loss sent to incineration without energy recovery, marking a significant milestone in our waste management journey. This achievement reflects our strong commitment to advancing sustainable and circular economic practices by eliminating low-value disposal methods and prioritizing recovery solutions that return value to the system.

Rather than incinerating food loss without any energy benefit, we have redirected these streams into higher-value alternatives such as animal feed production, composting, bioenergy generation, and co-product development. These efforts are part of our broader strategy to ensure that more than 99% of all tuna parts are utilized, supporting our Dry Concept Strategy to maximize resource efficiency and minimize waste generation at the source.